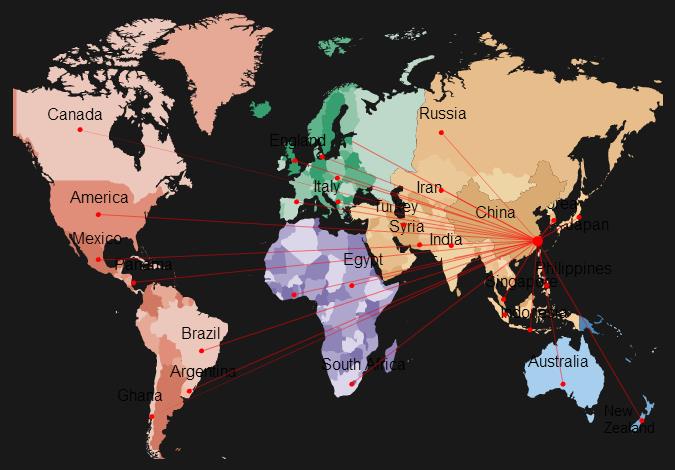

Nail Making Machine

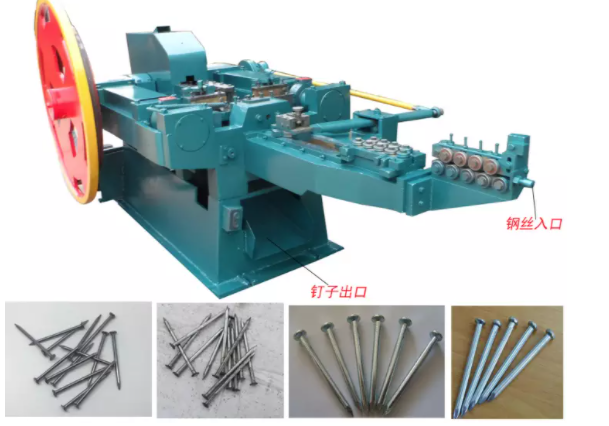

Nail making machine is made of scrap steel which diameter is below 8 mm, length is more than 10 cm, such as new dish round as raw material. To use wire drawing machine wire drawing first (to the diameter of the nail), and then made nails, nail making machine and polishing machine polishing, knife grinder screw grinding machine tool. It’s mainly used for manufacturing all kinds of nails. Both scrap and new steel wire can be used to make nails.

Adopts piston structure to ensure the high working speed, low noise, high dimension accuracy and less chance of impact

characteristics, especially can make excellent quality. These nails and other special-shaped nail which suitable for high speed studs for welding machine and nail gun. It can automatically provide materials for materials, only1-2 workers could operate whole plant.

Features of nail making machine:

- Nail making machine has the features of small in size, easy to move, low noise, low powerconsumption, and it is easy to operate, just need to change different size mould for making different diameter nails, if you wantto make different lengths of nails for same diameter, no need to change anything.

- Nail making machines can feed the materialsautomatically, and making nail body straight, nail points sharp and symmetric, nail caps round. Each nail made from this machineries excellent and perfect.

- Main components (shaft, cams and gear) of nail machine are made of high quality steel, and durable in use, has good stability.

- Especially, our nail making machine can make the high quality of oil rivet nail and other shaped nails used for high speed welding nail and nail gun.

- Feature of our nail making machine: Using plunger type structure to ensure the high working speed, low noise, and less chance of impact. It has the features of advanced design, compact conformation, and good type. It is easy and safe to operate.

Previous:CNC Dovetail Tenoner